SITI

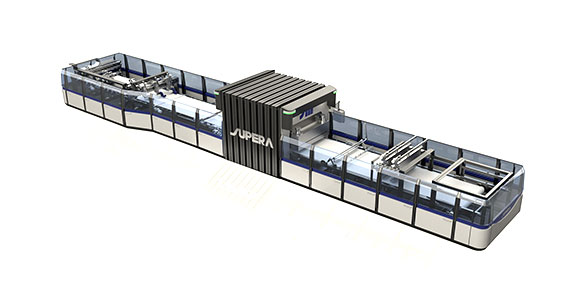

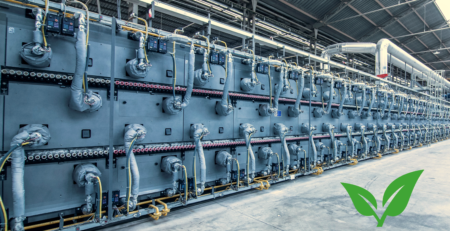

La soluzione completa per i produttori di piastrelle e lastre ceramiche

Progettazione e produzione di tecnologie di pressatura, essiccazione, cottura e scelta per l’industria ceramica.

Offerta completata da soluzioni per body preparation, macinazione, stoccaggio e movimentazione.

Tradizione e Qualità,

Efficienza e Competenza,

Velocità e Affidabilità

ASSISTENZA

B&T Care

Un servizio di Customer Care completo che segue il cliente step by step grazie alla rete di filiali presenti in tutto il mondo.

La vicinanza ai territori permette a Siti di diventare partner dei propri clienti attraverso una pronta assistenza tecnica, servizi di manutenzione ad hoc e una linea di consumabili proprietaria per migliorare le prestazioni delle tecnologie.

NEWS